KARL SCHNELL GmbH & Co. KG

Booth number: S1-F53

www.karlschnell.de

About us

PARTNER TO THE FOOD INDUSTRY – we offer solutions, not just a product!

KARL SCHNELL, based in Germany, is a world leading supplier of automated production systems for various food applications.

In over 75 years of company history, the name KARL SCHNELL has become an internationally recognised term in the food industry.

It represents a machinery construction company which combines perfected technology with constant innovation. By consistent application of this concept, we have become a leader in the field.

Today the key business of KS is creating solutions for the industrial processing of meat, pet food, delicatessen and processed cheese.

KS offers a wide range of food processing machines fo the market, which encompasses a diversity of systems.

The high vertical range of manufacturing at KS guarantees, that machines and equipement are from a single source – individually customtailored, reliable and with uncompromising quality.

Address

Muehlstr. 30

73650 Winterbach

Germany

E-mail: ks@karlschnell.de

Phone: +49 7181 9620

Internet: www.karlschnell.de

Contact person:

Claudia Kaesser

E-mail: ks@karlschnell.de

Products & Services

Food processing machinery (sausage and meat products, dairy products, fish, convenience, delicatessen), Cheese processing machinery (IWS, SOS, cream cheese), Pet food processing machinery (chunks-in-gravy, all meat, dry pet food),

Fully automated production lines,

UHT technology (pasteurization and/or sterilization),

Emulsifying technology, Filling technology, Development and planning, Service, Breaker, Grinder, Mixer,

Emulsifier, Vacuum Filler, Storage equipment, Conveyor equipment, Process Automats

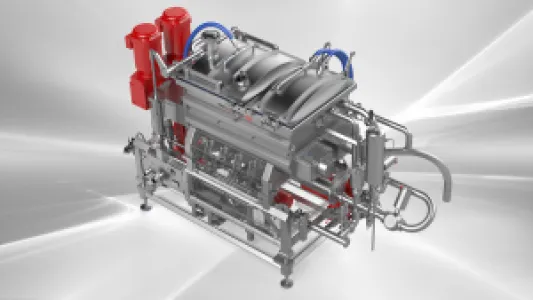

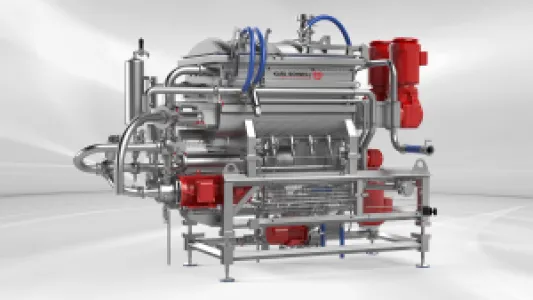

More than just a mixer – the KS Mixing Centre 600 V

High-end solution for modern production processes

The KS Mixing Centre 600 V from KARL SCHNELL is far more than just a conventional mixer – it is an innovative process centre for the flexible, efficient, and high-quality processing of a wide variety of food products. Developed for the demanding requirements of the food industry, this system combines the advantages of a low-shear mixer with an integrated high-shear emulsifier, fed by a pump directly below the mixing vessel. This opens up completely new process possibilities – from gentle premixing to precise emulsification under high vacuum.

Innovative functionality meets maximum flexibility

The KS Mixing Centre 600 V is specially designed for the processing of highly viscous and shear-sensitive products under vacuum. The combination of low-shear mixing and high-shear emulsifying enables products to be processed particularly homogeneously, gently, and efficiently. Dry substances can be effectively dispersed in liquids – without clumping and with high uniformity.

Flexibly selectable process paths:

Conventional further processing: The mixture is transferred to a connected buffer tank and continuously fed to the downstream production unit.

Direct emulsification: The integrated product pump conveys the premix directly under vacuum to the emulsifier, which processes the product into a homogeneous emulsion using the high-shear process.

Recirculation and combination: After emulsification, the product can be pumped back into the mixing tank to be refined with coarse additives. The product is then discharged directly via a bypass.

This system architecture combines the advantages of a process automat with the strengths of a mixer, offering unprecedented process control. Thanks to the controlled pump feed to the emulsifier, precise temperature control is guaranteed – under vacuum conditions, which is crucial for product quality. This allows even sensitive formulations to be implemented reliably and reproducibly.

Benefits at a glance:

• Combination of mixing and grinding technology in one system

• Modular design for maximum adaptability to individual process requirements

• High-vacuum process control that improves product quality and shelf life

• Flexible further processing depending on requirements

• Efficient emulsification and homogenisation, even for complex products

• Precise control of temperature, mixing intensity and product flow

Complementary aspects of the KS mixer portfolio

The KS Mixing Centre is part of a comprehensive portfolio from KARL SCHNELL, which includes mixing systems in a wide range of sizes and configurations – from 30 to over 7,000 liters. Thanks to intelligent PLC control, separate motor control, vacuum intake for powder components, and precise temperature control, all production requirements can be reliably met. Its reproducibility and integration into continuous production lines make the system an ideal solution for the highest demands on quality and efficiency.

Conclusion

The KS Mixing Centre 600 V offers a unique combination of flexibility, process reliability, and efficiency. It is ideal for producers who demand the highest quality while simultaneously producing complex products economally – a true centre of innovative food processing.

Smart up your production – visit us at the German Pavilion

Discover other innovative solutions from KARL SCHNELL and find out more on our homepage www.karlschnell.de

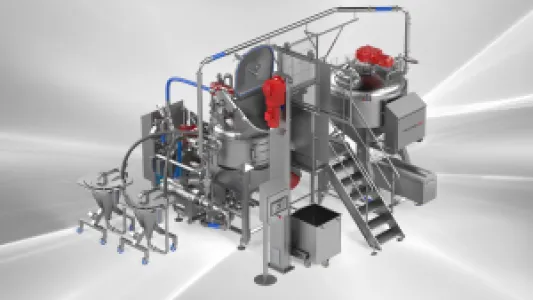

KS Process Automats - Modern processing for smart product ideas

Innovation as a success factor

The development and introduction of innovative recipes and products is becoming increasingly important for producers of meat products, processed cheese applications and vegan alternatives. In order to exploit the full potential offered by the success factor of innovation, a modern, flexible machine park is required, together with a high level of technological know-how. This is the basis for a real competitive advantage and a successful product launch.

Reproducible, consistent quality is essential for producing this type of high-quality food. Furthermore, gentle processing and precise ingredient dosing are required in this sensitive area to achieve the best possible flavor in the final product.

All-In-One Solution Process Automat

KS Process Automats offer maximum process reliability and efficient production flow - with significantly reduced batch times and low energy requirements.

State-of-the-art ergonomic agitator tools mix and homogenize the individual ingredients of the formulation sustainably - without lump formation in the shortest possible time. The desired degree of emulsification can be freely adjusted. When processing fine emulsions, the use of the integrated emulsifier is indispensable and particularly effective.

In order to cope with the large number of different applications, the product temperature can be set with direct or indirect temperature control. The use of the vacuum system also guarantees permanent evacuation of the product during processing.

In addition to the automatic metering of additives from different silos and containers, complete integration of the machine control into an existing higher-level plant control system is also possible. This ensures that the product to be produced is delivered to the desired location in the desired quantity at all times. A wide variety of recipes can be stored in order to react flexibly to different products or product changes. The high degree of automation ensures precise, reproducible food production.

Intermediate cleaning of the machine, even during ongoing production, is performed by the CIP (cleaning in place) connection. The result of this self-contained system is the highest standard of hygiene without contamination or cross-contamination.

The automation in processing ensures standardisation. This guarantees the production of a wide range of permanently high-grade products in constant quality. In addition, it enables producers to react always with flexibility to the market and to position themselves optimally for the future.

Smart up your production – visit us at the German Pavilion

Discover other innovative solutions from KARL SCHNELL and find out more on our homepage

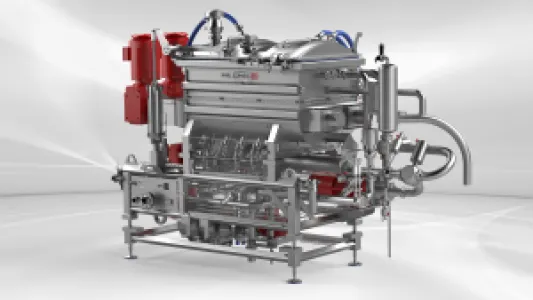

Innovative hygiene solution for the highest demands: KS DSE-Series Emulsifiers

As a holistic solution provider, KARL SCHNELL is setting standards in terms of hygiene, efficiency and precision in the ultra-fine comminution of food with the new DSE-Series. The machines combine state-of-the-art technology with an uncompromising hygienic design, thus offering clear added value for demanding production environments.

Hygienic design according to the latest standards

The DSE-Series consistently meets the latest hygiene guidelines of the food industry. The modular motor unit is made of stainless steel and certified to protection class IP69 – ideal for use in wet rooms. The hygienic water cooling and energy-efficient, low-noise continuous operation guarantee maximum operational reliability.

Powerful drive

With a maximum power of 150 kW and a variable speed range from 50 to 4500 rpm with constant torque, the universal drive unit offers maximum flexibility for a wide variety of applications. The axially adjustable motor shaft enables precise and loss-free adjustment of the cutting set during operation – for optimal knife positioning and minimal wear.

Versatile emulsifying unit

Benefit from the world's largest range of cutting systems and the unique ability to combine different cutting principles in one machine. This enables the production of homogeneous, ultra-fine products in a single operation – with the highest performance and maximum process reliability.

Hygienic Cutting System HCS

For particularly hygienically sensitive applications, KARL SCHNELL offers the world's first CIP-cleanable multistage cutting system HCS. The system sets new standards in the area of product safety, particularly with regard to the prevention of bacterial contamination and cross-contamination.

The HCS was designed for the gentle processing of low to medium viscosity, non-abrasive and short-fibre products. Typical applications include the production of delicatessen, baby food, ice cream, cream cheese and processed cheese.

The complete unit consists of a modular cassette housing optimised for CIP cleaning with an integrated bladeless special cutting set and a high-performance sealing system.

Cleaning takes place in a closed state, eliminating the need for blade changes and cutting set disassembly and ensuring continuous operation.

Precise regulation with KS Smart Control

The intelligent control system continuously monitors temperature and system status and enables definable shear positions as well as temperature-dependent automatic expansion correction. Different user levels are managed via personalized RFID login. Control is carried out directly on the machine via PLC and can be seamlessly integrated into existing systems.

Optional product feed

The optionally available KS Feed Hopper with integrated screw ensures precise temperature control – even with highly viscous materials – and further increases production speed.

Available in two versions: FD and FL – optimally adapted to specific requirements.

KS DSE-Series Emulsifiers – for maximum hygiene, top product quality, and efficient processes in food production.

Smart up your production – visit us at the German Pavilion

Discover other innovative solutions from KARL SCHNELL and find out more on our homepage

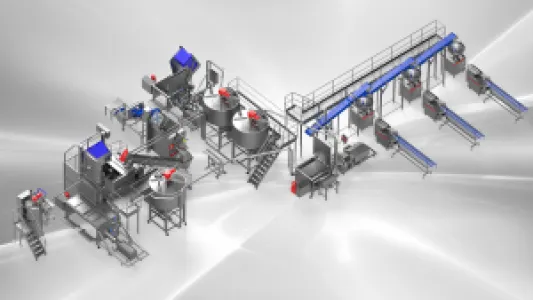

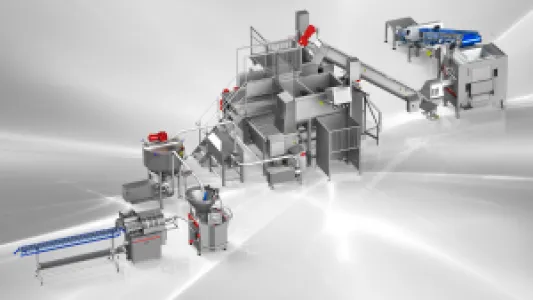

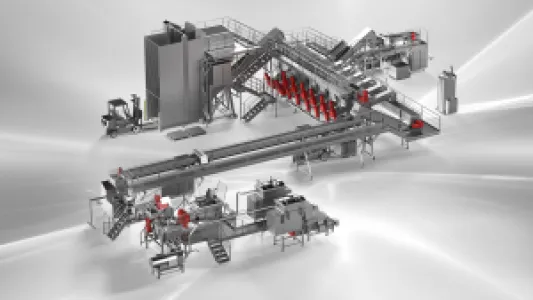

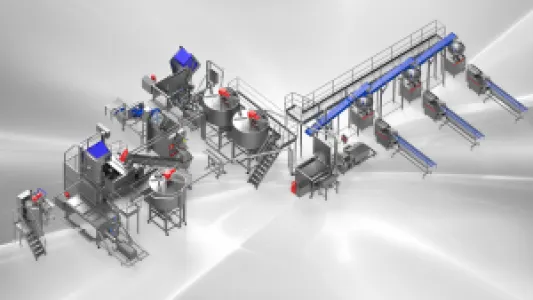

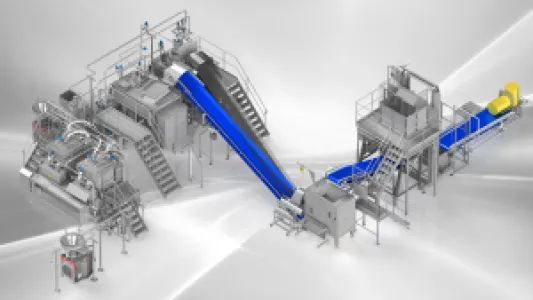

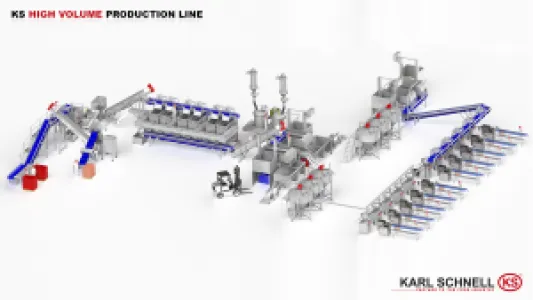

Production lines from KARL SCHNELL - process competence from a single source

The market for sausages, meat products and meat alternatives is changing quickly. Consumer demands are evolving rapidly – and with them, the demands placed on producers. Today, greater product variety, smaller batches, short response times, and, at the same time, economical large-scale production with consistently high quality are required.

Your line – your success

KARL SCHNELL offers the ideal answer to these requirements: fully automated, highly flexible, and individually designed production lines for food processing. All components are optimally coordinated – for maximum efficiency, process reliability, and product quality.

Suitable concepts for every challenge

From raw materials to finished filling, KARL SCHNELL develops sophisticated line concepts with breakers, grinders, mixers, conveyor technology, and high-performance emulsifiers. Decades of experience and a high level of vertical integration enable system configurations that are impressive even in confined spaces and for special product requirements.

More performance. More possibilities.

Innovative KS high-performance vacuum fillers and flexible buffer solutions ensure a continuous production flow. For specialty products or small operations, KARL SCHNELL also offers a wide selection of high-performance individual solutions.

Freedom for your ideas.

With innovative controls, easy operation, and modular expansion options, you remain flexible at all times and ready for new market trends. And for individual requirements, we deliver equally high-performance tailor-made solutions – customized, efficient, and reliable.

Smart up your production – visit us at the German Pavilion

Discover other innovative solutions from KARL SCHNELL and find out more on our homepage

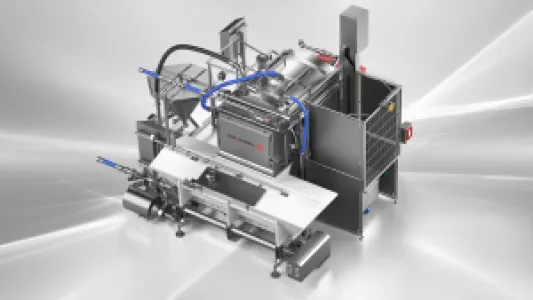

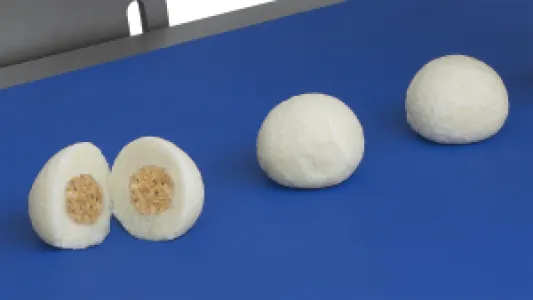

KS Diaphragm Koex - The solution for filled products!

The solution for filled products!

The KS Diaphragm Koex is a multifunctional portioning device in the food sector for processing all pasty and dimensionally stable products with internal filling.

Equipped with a modern drive concept based on a highly dynamic servo motor, a wide variety of food products can be portioned. And this in many sizes and individually configurable ratios of outer shell and filling.

The range of applications is enormous:

From mini meat or cheese balls to large potato dough and bread dumplings

Sweets in many shapes and types

moreover long products such as filled croquettes or cevapcici, and many more…

The type of filling as well as its consistency can vary - from low viscous sauces to highly viscous emulsions with chunky fillings - everything is possible.

The integrated filling flow divider ensures exact weight accuracy per lane and product. This enables the best possible efficiency in the use of raw materials with consistently high product quality.

We offer two systems tailored to the customer's area of application:

- Control piston system - for use in continuously operating, high-capacity production lines

- Vane cell system - for flexibility in the downstream production process

Product injection - so-called coextrusion - thus allows a wide range of design possibilities, not only in terms of the

specification and consistency of the two starting materials, but also their filling ratio to each other.

There are several options for dispensing the product:

- Dispensing onto a belt conveyor, for example, for further processing in a breading line or laminating system or for transfer to subsequent conveyors

- Direct dispensing into a water bath or oil bath system

- Dispensing onto a rolling belt for defined ball shaping for a variety of dumpling products.

Centrally controlled via KS Vacuum Fillers of the P-Series, the filling machines, portioning device and output conveyor form a single unit. In addition, the electromotive height adjustment of the complete diaphragm module offers easy and convenient

positioning via the downstream production line.

The central servo concept for all drives ensures precise conveying and portioning with gram accuracy. All functions can be visualized and easily operated on the clearly arranged, swiveling operator terminal.

The specification and size of the product to be manufactured can be modified with just a few quick-change parts.

This guarantees easy cleanability and best hygiene.

The modular design and the flexible combination options of the individual modules ensure efficient, ergonomic work with optimum production capacity utilisation.

Smart up your production – visit us at the German Pavilion

Discover other innovative solutions from KARL SCHNELL and find out more on our homepage www.karlschnell.de