Jumag Dampferzeuger GmbH

Booth number: S1-D36

www.jumag.de

About us

For over 45 years, JUMAG steam boilers have stood for quality, reliability and innovation in the field of steam technology. As a leading manufacturer, we offer tailor-made solutions that meet the high requirements of the beverage industry. Our steam boilers combine the efficiency of a water tube boiler with the compactness and flexibility of a quick-acting steam boiler. This enables us to offer you particularly energy-efficient and environmentally friendly steam generation that also guarantees maximum process reliability.

Address

Badener Str. 8a

69493 Hirschberg

Germany

E-mail: huechting@jumag.de

Phone: +49 162 2806860

Internet: www.jumag.de

Contact person:

Urs Hüchting

E-mail: huechting@jumag.de

JUMAG DG 560

JUMAG DG560 – High-Performance Steam Boiler

The JUMAG DG560 is a gas or oil-fired steam boiler with a steam output of up to 560 kg/h. It combines the advantages of large shell boilers with the compact size and rapid readiness of quick steam generators.

Key Features:

Steam output: up to 560 kg/h

Fuel options: Natural gas, LPG, light oil

Efficiency: Up to 97% (over 100% possible with heat recovery systems)

Control system: Fully automatic with touch display and remote monitoring capability

Design pressure: Up to 11 bar (custom pressures available)

Compact footprint: Ideal for limited space or containerised use

No continuous supervision required in many regions due to certified safety system

Advantages:

Low energy consumption and fast start-up times

Very low maintenance thanks to patented pump circulation system (no water level electrode)

Easy integration into modular and multiple-boiler systems

Long service life with stainless steel components and industrial-standard burner

Applications:

The DG560 is suitable for industries such as food production, pharma, textiles, automotive, and cleaning – wherever medium steam output with high reliability is required.

JUMAG EDI series

JUMAG EDI Series – Electric Steam Boilers (20 to 120 kW)

The JUMAG EDI series includes compact, fully electric steam boilers with outputs ranging from 20 kW to 120 kW, corresponding to approx. 30 to 180 kg steam per hour.

Key Features:

Steam output: Approx. 30–160 kg/h

Power range: 20 kW to 120 kW

100% electric: Ideal for decarbonised or renewable energy use

High efficiency: >97% with modulating load control

No flue gas system required: Emission-free operation

Touch-screen control with remote monitoring option

Quiet operation and minimal maintenance requirements

Design Highlights:

Robust stainless steel pressure vessel

Generously sized evaporator surface with integrated drop separator for dry steam

Modular heating rod system with load control via thyristor technology

Fully automatic blow-down and feed water management

PED and CE compliant

Advantages:

Quick start-up, low energy loss in standby mode

Very compact – ideal for restricted space or indoor installation

No combustion air or chimney required

Can be integrated into skid or container systems

Suited for clean environments (labs, pharma, F&B, etc.)

Applications:

Perfect for industries with low to medium steam demand and high requirements for clean, emission-free operation – such as food production, pharmaceutical, healthcare, cosmetics, textile, and laboratories.

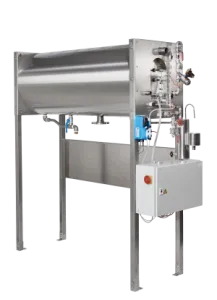

JUMAG EDI 360

JUMAG EDI 360 – Electric Steam Boiler (360 kW, 480 kg/h)

Primary Features:

Steam output: Up to 480 kg/h (~8 kg/min) from a 360 kW electric heating system

Compact design: Slim dimensions (approx. 1,965 × 990 × 1,425 mm), suitable for tight or containerized setups

Pure steam quality: Large water volume and drop separator ensure dry, high-purity steam; stainless-steel media-contact parts enable ultrapure steam production

Technical Highlights:

Approved under PED category III (no constant supervision required)

Working pressure range: 3–11 barg (up to 13 barg relief limit)

Heats up from standby to steam in approx. 5 minutes (material-compatible)

Robust heating system: stainless steel rods, controlled via thyristor modulaton for uniform wear, reducing stress on power grid

Operational Benefits:

Very compact footprint allows flexible placement indoors or in container units

Full touch-screen control with multilingual interface and remote monitoring capability

Integrated cooling circuit with heat recovery further enhances efficiency

Low-maintenance and highly reliable, backed by 24/7 customer support

Applications:

Ideal for medium-to-high steam demand in clean environments—hospitals, laboratories, pharmaceutical production, and food & beverage industries where pure, emission-free steam is essential

JUMAG EDITORS 960

JUMAG EDI 960 – High-Capacity Electric Steam Boiler

The JUMAG EDI 960 is a fully electric steam boiler designed for industrial applications with high steam demand. With a heating capacity of 960 kW, it delivers approximately 1,280 kg of steam per hour.

Technical Specifications:

Electrical power: 960 kW

Steam output: approx. 1,280 kg/h

Operating pressure: up to 11.5 bar

Boiler category: PED IV

Water content: approx. 1,400 litres

Heating system: 12 stainless steel heating rods (80 kW each) with thyristor control

Dimensions (L×W×H): approx. 2,620 × 1,910 × 2,150 mm

Weight: approx. 4,500 kg

Key Features:

Modular heating system: continued operation possible even if one heating rod fails

Thyristor-controlled load regulation ensures smooth operation without power surges

High-quality steam: integrated drop separator ensures dry steam

Optional integrated heat recovery and feedwater preheating

Large water surface area prevents foaming and enables high steam quality

Full automation with touch-screen operation and remote monitoring capability

Low maintenance due to robust design and industrial-grade components

Applications:

Ideal for clean and emission-free steam in industries such as pharmaceuticals, food and beverage, cosmetics, healthcare, and laboratories. Also suitable for integration with renewable energy sources.

Advantages:

High steam output with compact footprint

Emission-free and energy-efficient operation

No flue gas system required

Long service life and reliable performance

Suitable for 24/7 industrial use

-thumb.webp)

-thumb.webp)

-thumb.webp)

.png)