PROBAT SE

Booth number: S1-E34

www.probat.com

About us

About PROBAT

PROBAT has been a pioneer in developing innovative solutions for the coffee industry for more than 155 years. Through strategic acquisitions in the food technology sector, enhanced knowledge transfer within the group and continuous expansion of its global service network, PROBAT has established itself as a leading one-stop shop for the food processing sector. The company not only designs and manufactures machinery but also plans and implements turnkey industrial plants, environmental technologies, and advanced control solutions with integrated smart data management. PROBAT employs around 1,200 people at its subsidiaries in Brazil, Canada, India, Italy, Scotland, the Netherlands, and the United States. With a presence in over forty countries, PROBAT ensures its process expertise and experience are accessible to customers worldwide.

Address

Reeser Str. 94

46446 Emmerich

Germany

E-mail: info@probat.com

Phone: +49 2822 912-0

Internet: www.probat.com

Contact person:

Cheikh Sarr

Area Sales Manager – Coffee Industry

E-mail: c.sarr@probat.com

Phone: +49 2822 912223

Jens Roelofs

Head of Sales – Coffee Speciality

E-mail: j.roelofs@probat.com

Phone: +49 2822 912284

Frank Cone

Chief Commercial Officer – Food

E-mail: frank.cone@probat.com

Phone: +31 6 15855413

Products & Services

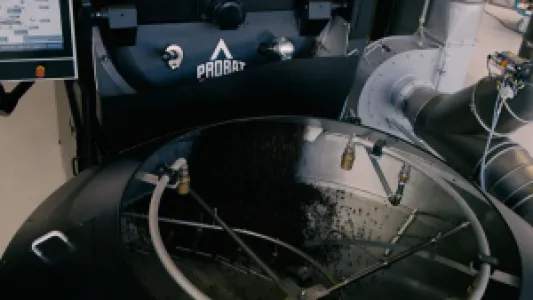

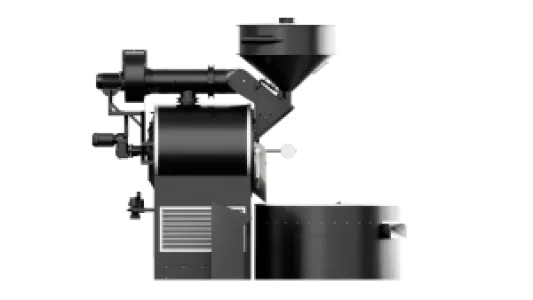

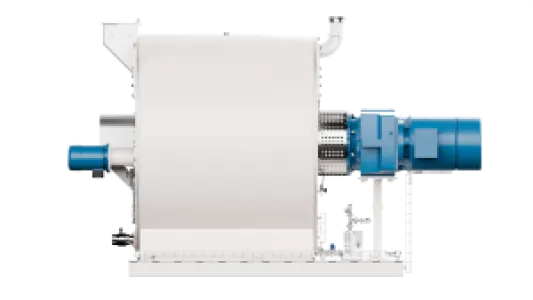

G series

Built to solve. Designed to deliver.

With their round contours and clean lines, the PROBAT G Series roasters are as visually striking as they are technically advanced. Designed for medium-sized roasting operations, these machines combine a sophisticated design with exceptional roasting performance, making them the perfect choice for businesses that value form and function equally.

With batch sizes ranging from 45 to 150 kg, the G Series consistently produces high-quality roasting results. Heat is transferred primarily via convection, with a controlled flow of hot air supplied through the rotating drum. This method delivers uniform bean development and excellent reproducibility across batches.

For added flexibility, the G45 model — visually aligned with the iconic UG series — offers manual airflow control, enabling roasters to create unique profiles and fine-tune flavour development. Standard features across all G models include the automatic emptying of the bean container, roasting drum and cooling sieve, which streamlines workflow and boosts efficiency.

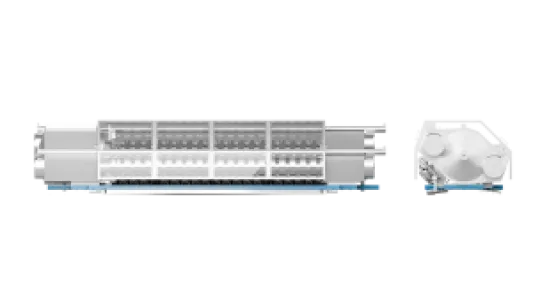

Refiner/Conche

Built to solve. Designed to deliver.

The MACINTYRE Refiner/Conche is an innovative, all-in-one solution that seamlessly integrates five key processes: cocoa nib grinding, pasteurizing, sugar grinding, mixing, refining, and conching – within a single, compact machine. Designed for flexibility and efficiency, it serves as a universal tool for the production of chocolate, compounds, coatings, pralines, truffles, and fillings, making it ideal for small to medium-scale manufacturing. Additionally, the MACINTYRE Refiner/Conche excels at processing a wide range of rework, further enhancing its versatility and value.

The Refiner/Conche features a specially engineered shaft with grinding bars and an adjustable pressure mechanism, allowing precise control over the product between the grinding and lining bars. This ensures a stable process and consistent product quality across batches

This all-in-one machine supports a flexible, step-by-step workflow:

Cocoa nib grinding – with optional pasteurization via water addition, heating, and rotation

Mixing – rotor rotation without applied pressure

Refining – rotor rotation with pressure on the grinding bars

Conching – rotor rotation with low or no pressure for smooth texture development

The Refiner/Conche functions as a stand-alone unit but is also engineered for seamless integration into a production line upstream of the BMC ball mill as an integral part of the MACINTYRE/WIENER Line. By combining mixing and pre-grinding in the Refiner/Conche with final fine grinding in the BMC, overall processing times are significantly reduced.

HPB Hydraulic Press Butter

Built to solve. Designed to deliver.

The Duyvis HPB Hydraulic Press Butter is the global industry standard for the efficient and sustainable extraction of cocoa butter. Its unique design, operation and materials deliver maximum output with minimum cycle times.

During the pressing phase, cocoa butter is efficiently extracted as it passes through the filter screens, which are precision-engineered and embedded in the press plates and counter pots. The filtered cocoa butter then flows seamlessly into drip trays and is channelled into a central conduit before being collected in a dedicated discharge vessel.

Once the pressing cycle is complete, the press opens swiftly and the residual cocoa cake is immediately discharged onto a conveyor belt. This rapid ejection minimizes cycle time and maximizes productivity. The cake is then transferred to a breaker unit where it is cut into uniform 'kibbled' pieces ready for further processing or packaging.

The HPB offers fully adjustable pressing cycles, providing precise control to accommodate the varying characteristics of cocoa liquor. This adaptability ensures consistently high-quality results, optimal fat content and consistent throughput across different production conditions.

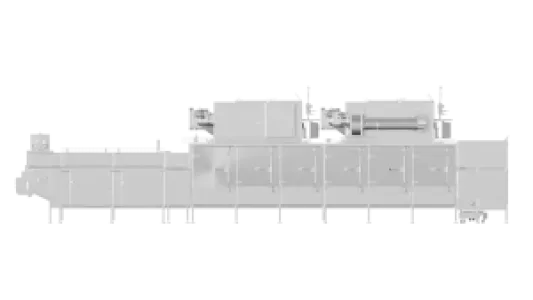

CRB Continuous Roaster Belt

Built to solve. Designed to deliver.

The Horn CRB Continuous Roaster Belt is expertly engineered to meet a broad spectrum of roasting and drying needs. Trusted by food processors worldwide, it delivers uniform, gentle treatment of peanuts, almonds, hazelnuts, sunflower seeds, and similar products—while also enhancing shelf life through integrated humidification.

Material enters the roasting section from the feed hopper where a stainless steel perforated slat conveyor moves it through each stage of the drying or roasting process. Enhanced heat zone air diffusion ensures uniform heat distribution for consistent product treatment.

An exhaust air temperature sensor continuously monitors product temperature and automatically adjusts burner power or airflow to maintain optimum conditions.

A built-in humidifier allows lower roasting temperatures, reducing acrylamide formation, improving de-bacterization and extending shelf life by minimizing fat oxidation.

Optimized air usage, pressure control and exhaust air recirculation deliver energy savings of up to 50%, while redesigned hopper covers protect against contamination and maintain process integrity during downtime.