Hansa Industrie-Mixer GmbH & Co. KG

Booth number: S1-F28

hansamixer.de/en/company

About us

HANSA MIXER – Engineering Precision for Food Innovation

For more than 40 years, HANSA MIXER has been developing high-precision mixing and aeration technologies that set global benchmarks in food production. Designed and manufactured in Germany, our machines are renowned for precision, efficiency, and hygiene standards that exceed industry requirements.

Whether for confectionery, bakery, dairy products, or innovative plant-based foods, our solutions ensure perfect textures, enhanced sensory experiences, and maximum production reliability. With customizable inline mixing and dosing systems, we help manufacturers bring new recipes to market faster, save energy, and optimize raw material usage.

Why HANSA MIXER?

Tailor-made machine concepts: Scalable from small batches to high-capacity production lines.

Hygienic design: EHEDG and FDA-compliant solutions for the highest food safety.

Innovative foam technology: Enhances taste and texture while reducing material usage and costs.

Global service and expertise: From consultation to commissioning – we support customers worldwide.

Guided by our motto "Make Best Products", we drive innovations that empower food manufacturers to achieve excellence on a global scale.

Address

Kronsbruch 6 – 8

28816 Stuhr

Germany

E-mail: kontakt@hansamixer.de

Phone: +49 4206 41600

Internet: www.hansamixer.de/en/company

Contact person:

Products & Services

Product & Service Overview – HANSA MIXER

Mixing & Aeration Machines

High-precision inline mixers for food applications

Customizable foam generators for confectionery, bakery, and dairy products

Modular systems scalable from pilot to high-volume production

Dosing & Injection Systems

Accurate inline dosing for liquid and gas ingredients, speciallity Flavor-Color-Acidity

Recipe-controlled processes for consistent product quality

Integration into existing production lines

Cleaning & Hygiene Solutions

EHEDG- and FDA-compliant clean-in-place (CIP) systems

Designed for minimal downtime and easy maintenance

Engineering & Custom Solutions

Tailor-made machine concepts based on specific process requirements

Support for new product development and process optimization

Expertise across food and non-food industries

Service & Support

Global installation, commissioning, and training

Preventive maintenance and spare parts supply

Process consulting for efficiency and sustainability

Industries Served

Confectionery, bakery, dairy, plant-based foods

Pharmaceutical, cosmetics, and specialty chemicals (non-food)

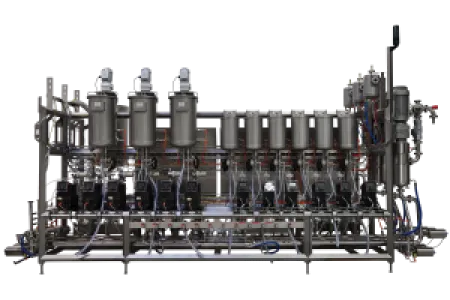

Dosing station

Dosing stations are suitable for all applications in which liquid media must be mixed continuously and with the utmost precision!

The dosing station shown here has a hygienic frame and beveled panels especially for use in the food sector.

Each dosing station is precisely tailored to the respective application

The individual station can be equipped with up to five lines

Five or more additives are possible per line

The dosing stations are specially designed for mixing pumpable media with different viscosities, as they can be operated at different speeds depending on the product

Mixing according to inline pH value and viscosity measurements is possible

As there are only minimal quantities in the mixing system, only very small quantities of waste need to be disposed of

An additional advantage is that the material filled in does not spoil as it only remains in the mixing system for a short time. It is possible to work with fresh products of consistent quality in every production process

As each dosing station is individually tailored to the requirements of our customers, the dimensions, and output ranges depend on the desired application.

Compact-Mix

COMPACT-MIX

Large production machine with up to three pumps built into the frame. Continuous aeration, whipping and mixing of pumpable media in the confectionery, baking or general foodstuffs industry.

Dynamic stainless steel mixing head available in three configurations: 570, 990 or 1,410 pins

Sterilisable construction of shaft seals, mixing heads fabricated from a single piece or laser-welded

Continuous electrically controlled RPM-adjustment (frequency converter) includes digital display

Exact dosing of flavourings or other ingredients possible using additional dosing pumps

Automatic systems, CIP-cleaning, temperature control devices and double-walled pipelines for effective production precisely conforming to your recipe

Reliable control of all production-processes using SPS-control system

Dimensions (L,W,H): 2,000 x 810 x 1,700 mm

Output range: from 50 – 400 kg/h to 300 – 2,000 kg/h

Lab Machine

Try before you buy

Putting foam quality to the test - with our unique laboratory test machine

"Try Before Buy": Test your processes before you invest

Precision is crucial in the development and production of foam products - both in the formulation and in the process. Our innovative laboratory and test machine offers you the opportunity to realistically simulate your foam processes and comprehensively test your product quality before purchasing a production machine. Thanks to our exclusive “Try Before Buy” program, you minimize investment risks, gain important insights and secure long-term competitive advantages. With a laboratory and test machine, you can rely on greater planning security, efficiency, and product quality.

Key features - your benefits at a glance:

Experimental setup: Research new recipes, process parameters and material combinations - under controlled but practical conditions. Ideal for research & development and feasibility studies.

Process identification and optimization: Determine the optimum production process for your specific requirements. Avoid bad investments and minimize your time-to-market.

Design efficient industrialization: Test your foam products under real conditions and lay the foundation for smooth industrial implementation.

Cost savings: Targeted preliminary tests save you time, material and unnecessary machine adjustments during subsequent operation.

Unique position on the market: Benefit from a testing option that is only available from us in this form - with comprehensive technical support from our team of experts.

Two flexible test options - here's how it works:

Tests at our technical center/laboratory:

Come to us and test your materials and processes together with our specialists at our premises. Alternatively, you can send us your products - we will carry out the tests for you and provide you with well-founded evaluations.

rental machine at your premises:

Would you like to test under real production conditions? No problem! For a rental fee, we provide you with the laboratory and test machine directly at your site for a defined period of time - without any long-term commitment, but with maximum knowledge gain.

The laboratory and testing machine is suitable for the following areas of application:

Product development in the non-food sector

Research

Teaching and training purposes

Production of small quantities

Technical data

Reliable scale-up of foam quality

Foam densities between 50 and 900 g/l

reproducible results by means of parameters such as foam density (overrun), product thickness, throughput, etc.

Temperature-controlled mixing head with double action mechanical seal

Easy to clean and maintain

SPS-controlled regulator with fully automated air volume control and user-friendly touch panel

Gasket-free eccentric screw pump with a temperature-controlled storage tank

Dimensions (L, W, H): 650 x 450 x 600 mm

Output range: 1 – 12 kg/h to 2-25 kg/

Top-Mix

The TOP-MIX

The TOP-MIX is a dynamic aerator for continuous aerating and whipping of both high- and low-viscosity media from all areas of the general foods industry. It’s main area of application is the broad field of the confectionery industry.

Can be used as a laboratory device, pilot system or production machine

Eroded mixing head fabricated from a single piece

Temperature-controlled mixing head (rotor/stator)

Can be used to process liquids with crystalline and particle content, acid and alkaline solutions, cold and hot media, powder and liquid mixtures and pastes

A particular advantage is that it can whip even the smallest quantities of material in combination with transferability to larger mixing systems

Dimensions (L, W, H): 800 x 600 x 600 mm

Output range: from 3 – 36 kg/h to 40 – 400 kg/h

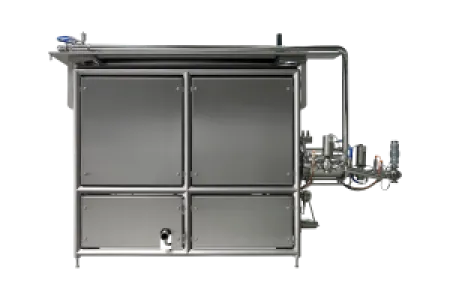

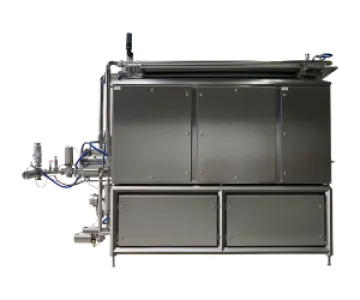

CIP-Cleaning

CIP-CLEANING

Regular, thorough cleaning maintains the quality of your products, increase the operational life of your machines and therefore protect your investments. You will find customised cleaning systems for every application and every requirement in our product catalogue.

Automatic cleaning systems with bypass and additional air injection

Operation directly via the display

Cleaning sequence can be changed

No need for time-intensive manual cleaning with removal of plant components

Depending on the particular product, water can be used with or without cleaning additives or you can use a product-specific solvent

As an alternative to the CIP system with receiver tank there is the option of direct connection to an in-house water line

Available in a few sizes.

Uni-Mix

UNI-MIX and UNI-MIX 2K

UNI-MIX and UNI-MIX 2K are ideal production machines when it comes to processing large quantities. They are perfect for use with complex recipe requirements in the confectionery industry, e.g. in marshmallow production.

Effective and precise production of large quantities of high-grade products to you specified recipe

Optimised construction, designed for the use of three and more pumps

An optional, separately driven mixing head expands the output range

Numerous possible variations of mixing heads, flow sensors, cleaning systems, seals, control systems and monitors

The optional special equipment ranges from specialised seals for mixing heads and pumps, various automatic systems such as volumetric or gravimetric flow sensors and foam height regulators (MA2) to temperature-controlled mixing heads

Dimensions (L,W,H): 2,000 x 1,000 x 1,820 mm

Output range: from 650 – 1,300 kg/h to 600 – 10,000 kg/h

or according to specification