Döinghaus cutting and more GmbH & Co. KG

Booth number: S1-E53

www.cuttingandmore.de

About us

We have been successfully managing our company "Döinghaus cutting and more". With a small team we have started to design individual machine and plant solutions for ultrasonic cutting for our customers in the food industry, confectioneries and bakeries. With success! Today, we have employed more than 50 employees, who are experts in their job and amaze our customers.If customers encounter problems in cutting their products, we will resolve the problems for them! Being a high-performance partner for ultrasonic cutting solutions, we respond to the complex customized requirements with innovative system techniques. Since we know, how optimum automatic cutting processes are being proceeded and the extent to which we succeed in guaranteeing safety and cutting accuracy.

Our customers include almost all well-known food manufacturers all over Europe. Moreover, we are also internationally active and have established permanent commercial partnerships worldwide.

Address

Breite Werl 30

33154 Salzkotten

Germany

E-mail: sales@cuttingandmore.de

Phone: +49 5258 2107-0

Internet: www.cuttingandmore.de

Contact person:

Erik Döinghaus

Managing Director

E-mail: erik.doeinghaus@cuttingandmore.de

Phone: +49 5258 2107-220

Dieter Döinghaus

Managing Partner

E-mail: sales@cuttingandmore.de

Phone: +49 5258 2107-0

Products & Services

Our machines in the overview

Being an efficient partner for cutting solutions with ultrasonic, the company Döinghaus cutting and more produces tailored machines and plants for the bakery and confectionery trade as well as for the food industry.

Whether you have rectangle or round products, creamy soft, crumbly or layered food, cold or warm material to be cut, products with nuts or other food such as sausages and cheese…

The multi-layered customised requirements are realised with innovative and efficient system techniques. Qualified choice of the correct plant components as well as the planning of the individual modules such as an optimised inflow technique.

Tray bake • Tarts • Cream rolls • Pizza • Sandwiches • Round cakes • Cheese • Pet food

Ultracut Filou - Compact universal cutter

The Ultracut Filou provides the full functionality of an ultrasonic cutter and convinces by the sophisticated ultrasonic cutting technology built in a compact machine. Round and square products or on a support will be cut in perfect quality by the plant. The individual piece sizes, segments and cutting speeds are freely adjustable via an intuitively operable touch panel.

The products can be easily inserted into the cutting area. Light grids secure the machine during the cutting process. The whole machine structure provides a maximum of hygiene and can be cleaned within a few minutes.

Multi-functional ultrasonic cutter

Compact machine design

Cutting on the cutting support or in the baking tray

Easy operation via touchscreen

Easy and rapid cleaning of the machine

Program-controlled knife cleaning with fresh water

Integrated KnifeGuard

Comprehensive cutting functions

Light curtain as contact protection

Comprehensive recipe management

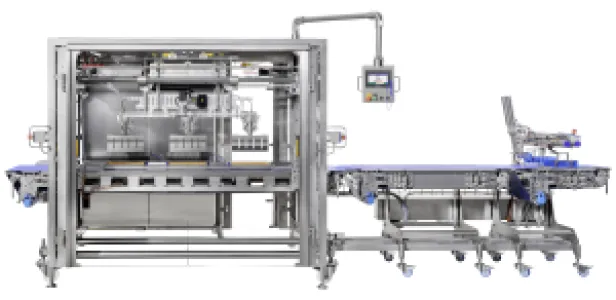

Ultracut Eos - Compact universal cutter with manifold cutter head

The compact Ultracut Eos stands out with its versatility. Using this ultrasonic cutting machine, it is possible to perfectly cut all baking tray sizes of up to 400 – 600 mm and round pies.

The products to be cut will be manually inserted into the machine. An encoded carrier plate system ensures a simple and exact centring of the products below the cutting head. A safety light grid at the front protects the operator and immediately switches off when activating the machine.

The machine is equipped with two or more ultrasonic cutters moving towards one another. They will automatically be positioned depending on the loaded recipe. The desired cutting pattern (recipe) will be entered via an easy-to-operate touch panel, withou0t the need for an additional programming.

Multi-functional ultrasonic cutter

Equipped with a multiple cutting head

Compact machine design

Cutting on the cutting support or in the baking tray

Easy operation via touch screen

Easy and rapid cleaning of the machine

Program-controlled knife cleaning with fresh water

Integrated Knife Guard

Versatile cutting functions

Ultracut Nado - Universal cutter with conveyor belt

The Ultracut Nado provides the full functionality of an ultrasonic cutter and impresses with its sophisticated ultrasonic cutting technology built in a hygienic machine.

Round and square products in the baking tray or on a support will be cut in perfect quality by the plant. The individual piece sizes, segments and cutting speeds are freely adjustable via an intuitively operable touch panel.

A conveyor belt will help the operator to convey heavy and large products in the machine. During the cutting process other products can be placed and baked goods that have been cut can be removed. Light grids secure the machine during the cutting process. The whole machine structure provides a maximum of hygiene and can be cleaned within a few minutes.

- Multi-functional ultrasonic cutter

- Compact machine design

- Man-sized doors, full accessibility

- Cutting freely on the belt and in the baking tray

- Cutting in the baking tray with tray detection

- Intuitively operable touch panel

- Easy and rapid cleaning of the machine

- Hygienic knife cleaning system

- Integrated Knife Guard

- Comprehensive recipe management

- Line-suitable

- Position detection via vision system

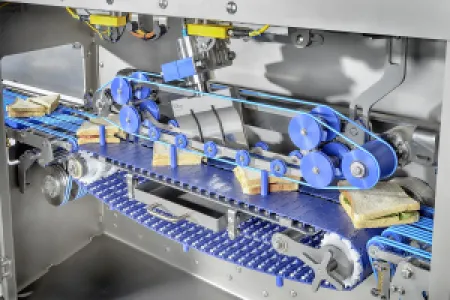

Sandwichboy – The compact sandwich cutter

The Sandwichboy cuts sandwiches and stuffed wraps of perfect quality. The products placed on the conveyor belt of the machine will be automatically aligned and conveyed through the cutting area. Then they can be removed from the conveyor belt.

The whole machine structure provides a maximum of hygiene and can be cleaned within a few minutes.

To cut sandwiches or wraps

Hygienic design according to the EHEDG directives

Easy and rapid cleaning

Usable as single or line machine

Compact machine

Fixable rollers

Depending on the product up to 70 cycles/min

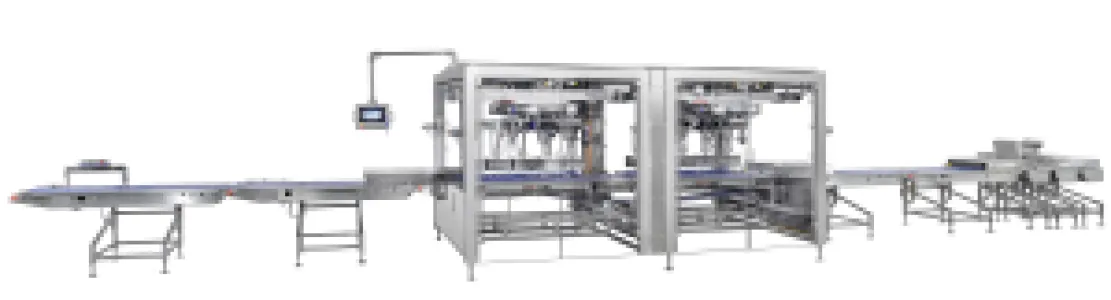

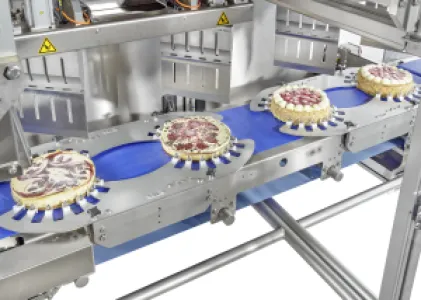

Ultrasonic cutting lines - Individual and customised

The ultrasonic cutting lines will be individually developed for you according to your customer-specific process parameters.

At this, the objective is to design an intergated and also a flexible automation solution, if requested. The cutting is performed synchronously for the conveying speed.

Synchronously working cutting line for endless products

Product separation

Automatic outward transfer to the cake edge

Combination with pick & place robots

Different types after technical clarification

Optimised prodction processes

Equipped with high-tech components

-thumb.webp)

-thumb.webp)