KERRES Anlagensysteme GmbH

Booth number: S1-F50

www.kerres-group.de/en

About us

KERRES: INNOVATION AND GROWTH SINCE 1966

Founded in 1966, KERRES has become a globally recognized provider of smoking and cooking systems. We have set industry standards with pioneering solutions such as the first floor-level combination chamber and most recently, the innovative Hybrid Air System.

The Hybrid System enables faster and more even product treatment, up to 30% shorter process times, reduced weight loss, lower energy consumption and consistently high product quality on all levels of the treatment trolley – whether for hanging or lying goods.

With systems in over 80 countries and modular solutions tailored to customer needs, KERRES stands for reliability, efficiency, and forward-thinking thermal processing technology.

Address

Manfred-von-Ardenne-Allee 11

71522 Backnang

Germany

E-mail: info@kerres-group.de

Phone: +49 7191 91290

Internet: www.kerres-group.de/en

Contact person:

Alex Milivojevic

Sales Director

E-mail: am@foodconsulting.ae

Phone: +971 52 2026032

Zvonko Cerkezovic

Managing Director

E-mail: zc@gewuerz.de

Phone: +49 160 4434410

Products & Services

Food Systems - Industry:

Universal Systems

Baking Systems

Cooking Systems

Showering and Intensive Cooling Systems

Semi-Continuous Systems

Climate Control Systems

Smoke Generators

Food Systems - Craft:

Universal Systems

Combined Chambers

Climate Control Systems

Cooking Kettles

Food - Cleaning Systems:

Pass-through washing machine

Bin washer

Large container washers

Transport trolley washers

Smoke stick washers

Non-Food:

Cleanline KLT

Universal Systems

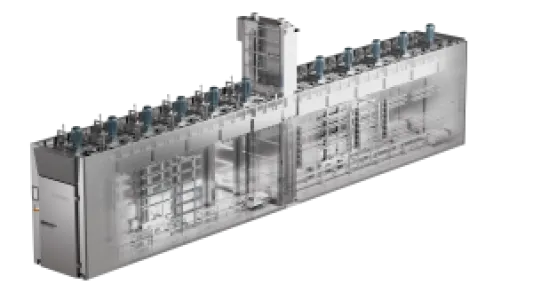

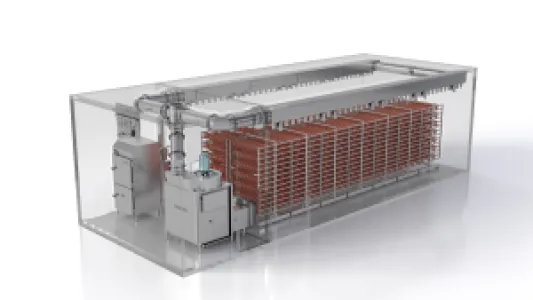

The KERRES Universal Systems: Unique Technology for Unmatched Flavor

Our universal systems set new standards in thermal food processing. Thanks to their modular design, they can be planned flexibly and installed easily – perfectly tailored to your individual requirements. The robust stainless steel construction is CE-certified, highly durable, and ensures the highest processing quality.

With our Hybrid System, you benefit from an innovative airflow technology that enables shorter processing times, higher loading capacity, and reduced energy losses. Additionally, the system optimally utilizes the generated smoke and operates environmentally friendly with minimal energy consumption.

Versatile Applications:

✅ Drying: Efficient and gentle moisture removal through uniform horizontal airflow – optimized processing times included.

✅ Smoking: Shorter transfer times ensure an even and intense smoky flavor.

✅ Cooking: Up to 30% shorter processing times and reduced energy consumption – less weight loss while maintaining maximum quality.

✅ Baking: Densely packed trays with even heat distribution for optimal baking results.

✅ Defrosting: Maximum loading efficiency with minimal spacing for fast and gentle thawing.

Your Advantages with the Hybrid System:

✔ Faster and more consistent processing of all products

✔ Reduced processing times by up to 30%

✔ Minimized weight loss due to optimized airflow

✔ Energy savings & lower operating costs

✔ Maximum loading capacity – hanging or lying

✔ Consistent product quality on all levels of the treatment trolley

✔ Sustainable and resource-efficient production with minimal energy consumption

Cooking Systems KK 2800

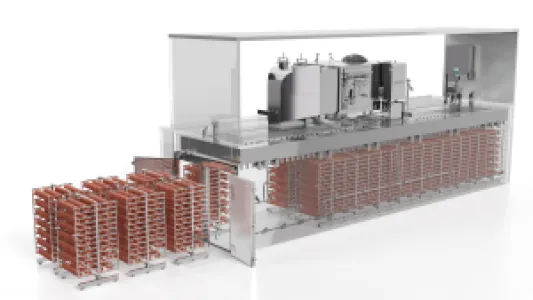

KERRES Cooking Systems – Gentle, Efficient, and Fully Automated

KERRES cooking systems enable fully automated and particularly gentle preparation of all types of food using steam cooking technology. This ensures that natural flavors, colors, and the appearance of the products are optimally preserved.

Thanks to the innovative KERRES recirculation technology, uniform temperature distribution is ensured within the system, allowing for high capacity utilization. The powerful two-stage reverse recirculation system ensures precise heat transfer and short processing times.

Your Benefits:

✔ Higher system utilization and uniform temperature distribution through reverse recirculation

✔ Gentle, microprocessor-controlled processes for optimal product quality

✔ Time and energy savings with high-quality fiberglass full insulation

✔ High steam density and minimal weight loss through integrated self-generated steam

✔ Up to 30% faster cooking times thanks to the proven KERRES reverse recirculation

At a Glance:

✔ KERRES Smart Control – Intuitive operation, available in multiple languages

✔ Energy-efficient motors

✔ High-quality stainless steel construction (V4A) for durability

✔ Single & multi-chamber models, fully insulated and ready for connection

✔ Adjustable interval injection system for self-generated steam

✔ Integrated foam cleaning system for easy maintenance

✔ Compatible with all common heating systems

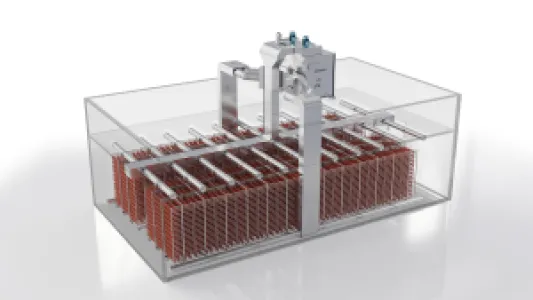

Climate control systems – for climate smoking, climate ripening, and post-ripening

Perfect Climate for Superior Taste

With KERRES climate systems, you can refine your meat, fish, cheese, and sausage products fully automatically and with exceptional care. Thanks to even product maturation, natural flavors, appearance, and color are optimally preserved. The innovative KERRES technology precisely and product-specifically controls the ripening process – ensuring consistently high product quality in every production cycle.

Tailored to Your Business

Every KERRES climate system is custom-designed and manufactured according to your size and functional requirements. This ensures you get the perfect system that seamlessly integrates into your space and production processes.

✅ Flexible capacities from 1 to 150 trolleys

✅ Semi- or fully automated cleaning systems

✅ Compatible with all common heating methods and refrigerants

Climate Smoking Systems for Refining Raw Sausage, Fish, or Cheese Products

Trolley arrangement: single- to three-row placement

Mixing chamber: can be mounted behind or on the unit

Available smoke generators:

Sawdust (RE)

Friction smoke (RR)

Heating types: hot water, electric, high- or low-pressure steam

Cooling options: Freon/Frigen, ammonia, brine, glycol, R64

Steam generation:

Via product's own moisture

Additionally through electric steam generation, low-pressure steam, or water injection via nozzles

Application areas: refining raw sausage, fish, or cheese products

Temperature range: +10 °C to +40 °C

Relative humidity: 80% to 95%

Capacity/room sizes: up to 30 trolleys

Stepless turbine speed control: airspeed from 0.5 m/s to 15.0 m/s

Stepless control of the damper motor

Outside air conditioning

Cleaning: high-pressure pump

Wide range of smoke generators available

Option: Utilization of waste heat from the refrigeration system by installing an additional heat exchanger

Climate Ripening Systems for Maturing, Drying, Smoking, and Conditioning Raw Sausage, Fish, or Cheese Products

Mixing chamber: can be mounted behind or on the unit

Heating types: hot water, electric, high- or low-pressure steam

Cooling options: Freon/Frigen, ammonia, brine, glycol, R64

Steam generation:

Via product's own moisture

Additionally through electric steam generation, low-pressure steam, or water injection via nozzles

Temperature range: +2 °C to +40 °C

Relative humidity: 80% to 95%

Capacity/room sizes: up to 100 trolleys

Stepless damper motor speed control: airspeed from 0.5 m/s to 15.0 m/s

Fully automated outside air conditioning

Cleaning: high-pressure pump

Option: Utilization of waste heat from the refrigeration system by installing an additional heat exchanger

Post-Ripening Chambers for Conditioning and Storing Pre-Matured Products

Unique 3D ventilation

Mixing chamber: can be mounted behind or on the unit

Heating types: hot water, electric, high- or low-pressure steam

Cooling options: Freon/Frigen, ammonia, brine, glycol, R64

Steam generation:

Via product's own moisture

Additionally through electric steam generation, low-pressure steam, or water injection via nozzles

Temperature range: +8 °C to +20 °C

Relative humidity: 76% to 80%

Capacity/room sizes: up to 120 trolleys

Stepless turbine speed control: airspeed from 0.5 m/s to 3.0 m/s

Stepless control of the damper motor

Fully automated outside air conditioning

Cleaning: high-pressure pump

Option: Utilization of waste heat from the refrigeration system by installing an additional heat exchanger

Smoke Generators

KERRES Smoke Generators – Perfect Smoke for Every Product

Whether you need smoldering smoke, wood chips, friction smoke, or liquid smoke – KERRES offers the right smoke generator for every application, flavor, and smoking system. Our advanced smoke generators ensure a consistent and controlled smoke production for optimal results.

From the beginning to the end of the smoking process, KERRES smoke generators maintain a constant smoke density and intensity, guaranteeing high-quality, reproducible smoking results every time.

Our smoke generators can be placed independently of the smoking chamber, allowing seamless integration into your production process.

Rely on maximum efficiency, precision, and quality – with KERRES smoke generators!

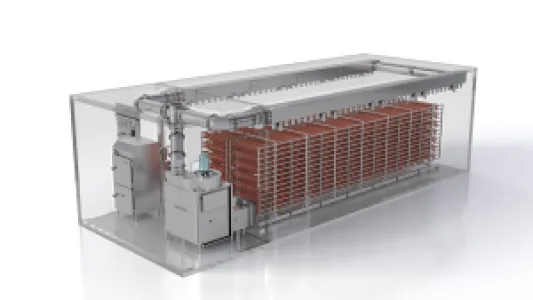

Cleanline Continuous Washing System

Specialized Washing Systems for the Food and Non-Food Industry High-Tech for Maximum Performance: The Cleanline Continuous Washing System

The Cleanline continuous washing system is specially designed for the cleaning of heavily soiled containers and equipment. It is suitable for use across all areas of the food and non-food industries and is ideal for cleaning plastic and metal containers, pallets, ham and pâté molds.

This system meets the highest hygiene standards, complying with strict food industry regulations. Thanks to its modular design, it can be individually configured and expanded at any time with additional modules.

Also Available in Our Product Range:

✔ KBW 202 Loading Trolley Washing Systems

✔ KBW 801 Large Container Washing Systems

✔ KRW Transport Trolley Washing Systems

Cleanline Continuous Washing System – At a Glance

✅ Durable stainless steel construction for maximum longevity

✅ Adjustable drive system for optimal performance

✅ Large cleaning and maintenance doors for easy handling

✅ Meets the highest hygiene standards of the food industry

✅ Modular system – expandable with pallet cleaning, cold and hot air drying, or mold cleaning modules

✅ Wide range of accessories & optional upgrades for customized solutions

Your Benefits at a Glance

✔ Fast & efficient cleaning and drying

✔ Economical & cost-effective

✔ Environmentally friendly with optimized water and energy efficiency

✔ Easy-to-clean system for maximum operational reliability

✔ Flexible modular design – adaptable to your needs

✔ Highest hygiene standards thanks to an advanced filtration system

✔ Available with all common heating types

✔ Also available as a 2-lane system

With KERRES specialized washing systems, you invest in efficiency, hygiene, and future-proof technology for your production!

-thumb.webp)